Start / Projects and skills

Our technical expertise: systems and fuels: professionalism and global standards of excellence

Strategic partnership with Cannon Bono Spa: the bridge between innovation and service

The collaboration with Cannon Bono, a world leader in thermotechnology with over 8,000 boilers installed in more than 40 countries, elevates IBS's service to a level of global excellence. IBS is not just a maintenance technician; we are the technical extension of an internationally recognized brand, which means, in concrete terms:

- Shared technology platform

- Direct access to the manufacturer's original construction diagrams and advanced technical knowledge.

- Continuous updates: Our technical team is trained at the factory (in Italy), which guarantees knowledge of the latest product developments and the use of products such as Siemens, Hitachi, Allen Bradley, F3 Automata; Camme Electronica – Weishaupt Wm100 and Plc S7 300, Ta Portal, Lamtec Burners, Riello, Dumeco, Fbr, Thermoregulators (Ascon, Gefran), Flow Meters (Rosemount, Hendress&Hauser).

Our professionalism is not limited to local intervention, but is based on operational and technical standards of international scope.

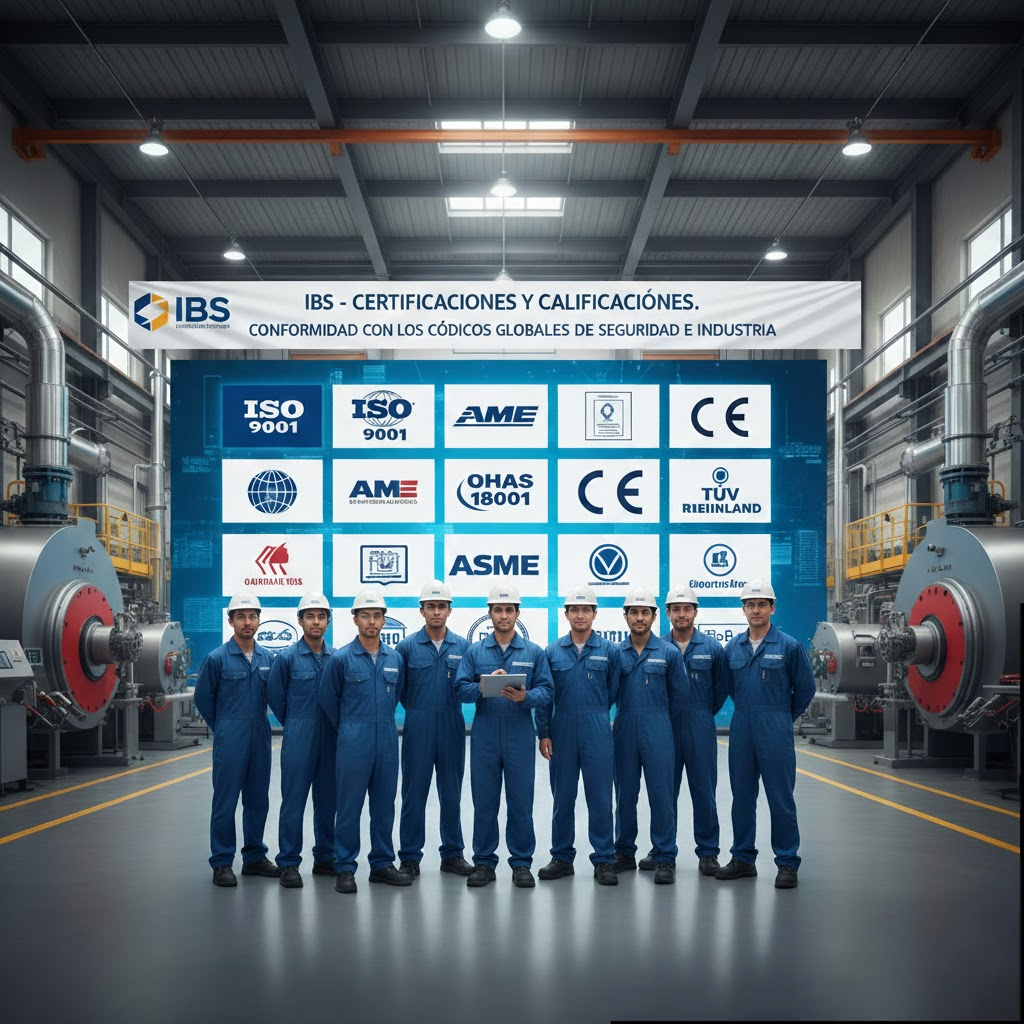

Certifications and qualifications

The IBS team operates in accordance with the strictest safety and industry codes worldwide.

International regulatory compliance

All our interventions, particularly commissioning and renewal, are aligned with the requirements of bodies such as PED (European Pressure Equipment Directive) and international guidelines such as ASME (American Society of Mechanical Engineers), where applicable for systems under maintenance.

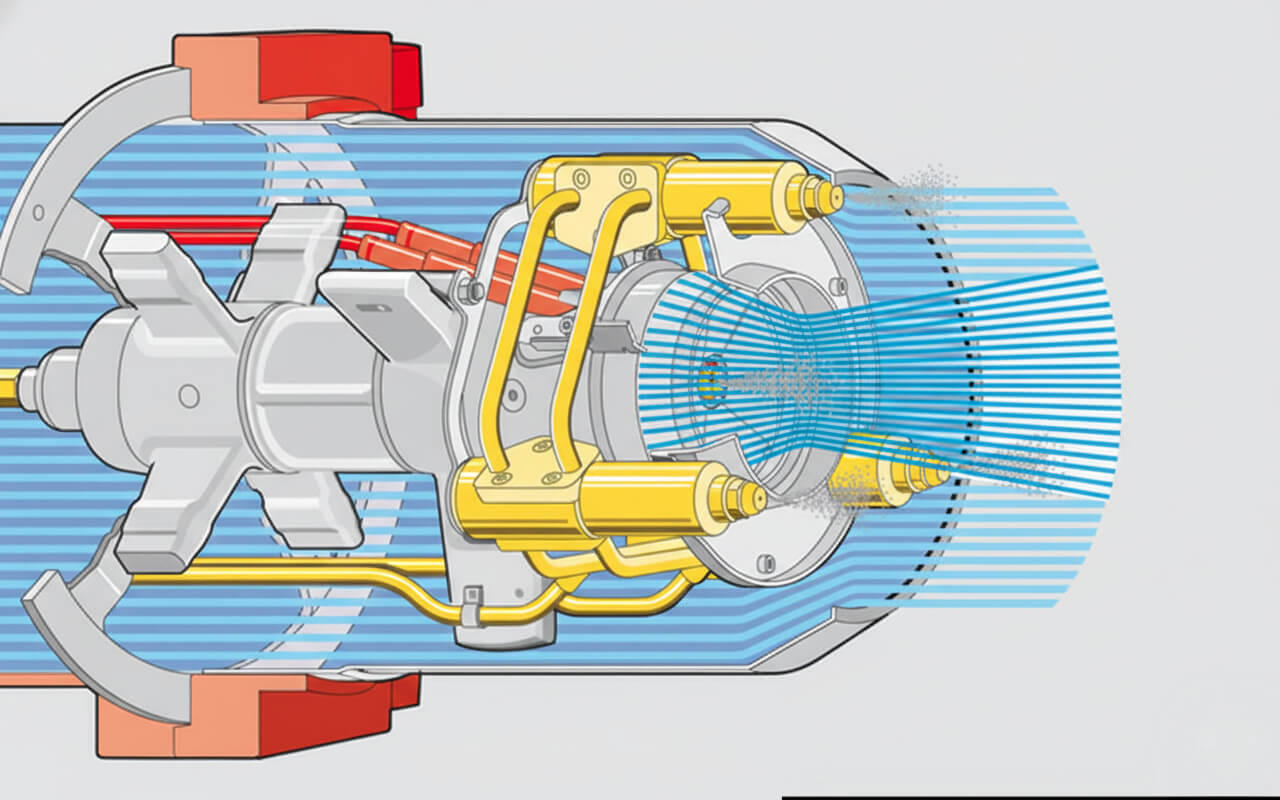

Specialization in burners

Our technical team is constantly trained and certified in the most advanced combustion systems

(for example, very low NOx burners), which guarantees not only efficiency, but also strict compliance with the environmental protocols of different jurisdictions.

Safety (HSE)

We adopt strict Health, Safety and Environmental protocols, which are essential for operating in these contexts.

complex industrial applications required by large international manufacturing and chemical companies.

Solving complex problems

Thanks to our database of case studies accumulated since 2018, we can address the unique thermal and mechanical challenges typical of multi-fuel and high-pressure plants. Our professionalism is demonstrated by our ability to:

- Diagnose intermittent faults or performance problems that other support services cannot resolve.

- Perform calibrations in critical environments (e.g., high temperatures or potentially explosive atmospheres - ATEX).